Automatic backwashing filters are essential components in water treatment systems designed to remove impurities and maintain clean, consistent water flow. These advanced filtration units offer a reliable solution for both residential and industrial applications by automatically cleaning themselves without the need for manual intervention. Among the various types of automatic backwashing filters, screen backwash filters, sand media backwash filters, and disc filter with automatic backwash are widely used due to their efficiency, durability, and ease of maintenance.

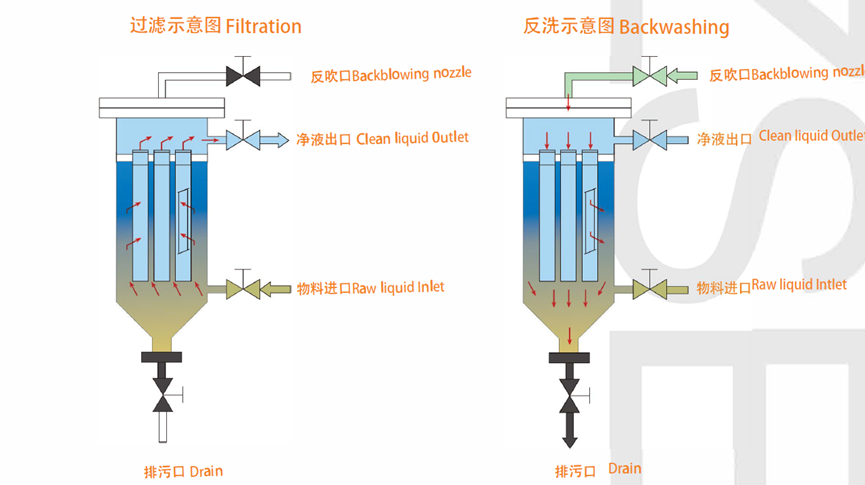

The key feature of an automatic

backwashing filter is its ability to detect when the filter needs cleaning based on pressure differentials or time intervals. Once triggered, the system initiates a backwashing cycle, reversing the water flow to flush out accumulated debris. This process ensures that the filter remains effective over long periods without requiring frequent shutdowns or replacements. The integration of smart control mechanisms allows these filters to operate efficiently while minimizing water waste and energy consumption.

Screen backwash filters utilize a fine mesh or perforated cylinder to trap particles as water passes through. When the pressure differential across the screen reaches a certain threshold, the backwashing mechanism activates, flushing the trapped contaminants out through a discharge valve. These filters are particularly suitable for applications where the water contains large amounts of suspended solids, such as in irrigation systems, cooling towers, and pre-treatment stages of drinking water plants.

Sand media backwash filters, on the other hand, use layers of sand or other granular materials to capture smaller particles and impurities. As water flows through the sand bed, contaminants are trapped within the media. During the backwashing phase, water is forced upward through the sand, loosening and removing the collected debris. This type of filter is commonly employed in commercial and municipal water treatment facilities where high levels of turbidity and particulate matter are present.

Disc filter with automatic backwash consists of multiple stacked discs that form a series of narrow channels. Water flows through these channels, and any particles larger than the channel size are retained on the surface of the discs. When the filter becomes clogged, the system performs a backwash cycle, rotating the discs to dislodge and remove the accumulated dirt. This design offers excellent filtration efficiency, especially in applications requiring precise particle removal, such as in food and beverage processing, pharmaceutical manufacturing, and aquaculture systems.

Automatic backwashing filters are versatile and can be adapted to a wide range of environments and water sources. They are commonly used in agricultural irrigation systems to protect drip lines and sprinklers from clogging. In industrial settings, they help maintain the quality of process water, reducing downtime and maintenance costs. Additionally, these filters are beneficial in swimming pools, spas, and recreational water facilities, ensuring clear and safe water conditions for users.

One of the main advantages of automatic backwashing filters is their low maintenance requirements. Unlike traditional filters that require regular manual cleaning or replacement, these systems operate autonomously, significantly reducing labor and operational costs. Their durable construction and efficient design make them ideal for continuous operation in demanding environments. Moreover, many models come with adjustable settings, allowing users to customize the backwashing frequency and duration according to specific water quality and usage conditions.

Users have reported positive experiences with automatic backwashing filters, citing improved water clarity, reduced maintenance efforts, and enhanced system performance. Many have noted that these filters provide consistent results over time, even in challenging water conditions. The reliability and effectiveness of these systems have made them a preferred choice for businesses and individuals seeking a long-term, cost-effective filtration solution.

Despite their benefits, it is important to choose the right type of

Automatic Backwashing Filter based on the specific application and water characteristics. Factors such as flow rate, particle size, and chemical compatibility should be considered when selecting the most suitable model. Proper installation and periodic inspection are also necessary to ensure optimal performance and longevity of the system.

Common questions about automatic backwashing filters often revolve around their efficiency, maintenance requirements, and compatibility with different water sources. Some users may wonder how frequently the backwashing cycle occurs or whether the system can handle high volumes of water. Others may inquire about the types of contaminants that can be removed or the impact of water pressure on filter performance. Understanding these aspects can help users make informed decisions and maximize the benefits of their filtration system.

In conclusion, automatic

backwashing filters represent a significant advancement in water purification technology. Whether it's a screen backwash filter, sand media backwash filter, or disc filter with automatic backwash, each type offers unique advantages tailored to different applications. By incorporating these systems into water treatment processes, users can enjoy cleaner, safer, and more sustainable water usage while minimizing operational disruptions and costs.