The High Efficiency Backwash Filter is a cutting-edge industrial filtration system designed to streamline the cleaning process and reduce manual intervention. This advanced device utilizes an automatic backwashing mechanism to ensure continuous operation without the need for frequent maintenance or downtime. Ideal for a wide range of applications, this filter is engineered to provide consistent performance, improved water quality, and long-term reliability. Whether used in manufacturing, agriculture, or municipal systems, the Automatic

Backwashing Filter offers a smart and efficient way to manage particle removal and fluid purification.

Key Features of the High Efficiency Backwash Filter

One of the standout features of the

Automatic Backwashing Filter is its ability to automatically reverse the flow of liquid to clean the filter media. This process eliminates the need for manual cleaning, significantly reducing labor costs and operational complexity. The filter is equipped with a robust and durable construction, ensuring it can withstand harsh environments and prolonged use. Additionally, the system is designed for easy integration into existing piping networks, making it a versatile solution for various industrial needs.

Another important characteristic is its high efficiency in capturing fine particles and contaminants. The filter’s multi-layered design allows for precise separation of impurities, resulting in cleaner output and extended equipment lifespan. Its energy-efficient operation also contributes to lower utility costs over time. The user-friendly control panel enables operators to monitor and adjust the system according to specific requirements, ensuring optimal performance at all times.

How Does an Automatic Backwashing Filter Work?

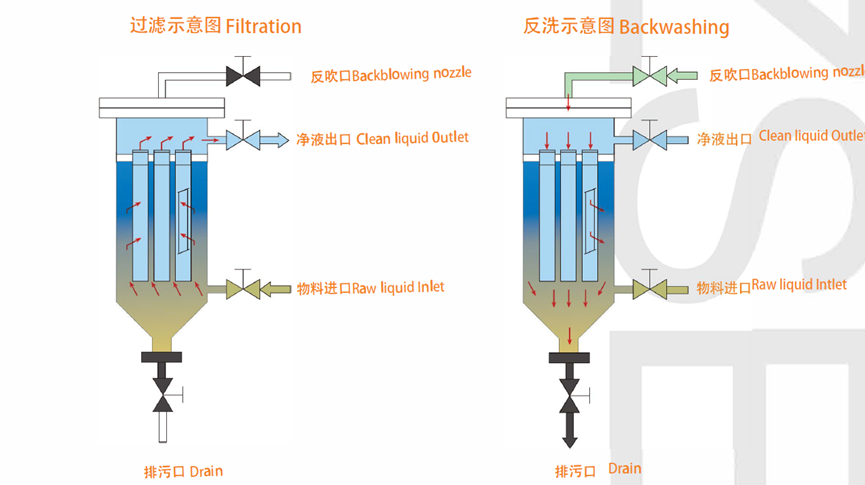

The working principle of an

Automatic Backwashing Filter is based on

a cycle of filtration and self-cleaning. During normal operation, the fluid passes through the filter media, where suspended solids and debris are trapped. Once the pressure differential reaches a pre-set threshold, the system initiates the backwashing cycle. This involves reversing the flow of liquid through the filter, dislodging the accumulated particles and flushing them out through a dedicated waste line.

This automated process ensures that the filter remains functional without interruption, maintaining a steady flow of purified liquid. The system is programmed to perform these cycles at regular intervals or based on real-time monitoring, depending on the application. By eliminating the need for manual cleaning, the Automatic Backwashing Filter enhances productivity and reduces the risk of human error.

The Labor Saving Industrial Filter is widely used across multiple industries due to its adaptability and efficiency. In the food and beverage sector, it helps in removing impurities from water, juices, and other liquids, ensuring product safety and quality. In the chemical industry, it prevents clogging and damage to sensitive equipment by filtering out harmful particles.

In agricultural irrigation systems, the filter ensures that water is free from sediment and debris, protecting crops and enhancing yield. Municipal wastewater treatment plants also benefit from this technology, as it aids in the removal of contaminants before discharge. Additionally, in cooling towers and heat exchangers, the filter maintains optimal performance by preventing buildup and corrosion.

User Feedback on the High Efficiency Backwash Filter

Users who have implemented the High Efficiency Backwash Filter in their operations consistently praise its reliability and ease of use. Many report significant reductions in maintenance time and costs, allowing them to focus on other critical aspects of their business. One operator noted that the system has improved their overall workflow by minimizing downtime and ensuring consistent filtration results.

Another user highlighted the system's durability, stating that it has performed exceptionally well even under challenging conditions. They appreciated the intuitive control interface, which made it simple to monitor and manage the filter’s operation. Overall, the feedback indicates that the Labor Saving Industrial Filter is a valuable investment for any facility looking to enhance its filtration capabilities.

Frequently Asked Questions About the Automatic Backwashing Filter

What are the main benefits of using an Automatic Backwashing Filter?

The primary advantages include reduced labor requirements, continuous operation, improved filtration efficiency, and longer equipment life.

Can the filter be customized for different applications?

Yes, the filter can be tailored to meet the specific needs of various industries, including adjustments in size, material, and control systems.

Is the backwashing process energy-intensive?

No, the system is designed to operate efficiently, using minimal energy while still delivering effective cleaning.

How often does the backwashing cycle occur?

The frequency depends on the system settings and the level of contamination in the incoming fluid. It can be adjusted to suit different operational conditions.

What types of contaminants can the filter remove?

The filter effectively captures a wide range of particles, including sand, silt, rust, and organic matter, depending on the filter media used.

Overall, the

High Efficiency Backwash Filter stands out as a reliable and innovative solution for

industrial filtration needs. Its automatic backwashing function, combined with its robust design and user-friendly features, makes it an ideal choice for businesses seeking to improve efficiency and reduce operational costs. Whether you are managing a large-scale production facility or a smaller processing unit, this filter offers a practical and effective way to maintain clean and safe fluid systems.